Whether you’re tackling odd jobs or a full blown fabrication task at home - an angle grinder is an essential piece of gear. Although a fairly simple power tool, a few minutes getting acquainted with its use will ensure success and safety.

Here's how it's done.

Tip 1 - Safety

Before you start, you'll need safety equipment:

- A decent pair of gloves

- Clear eye protection

- Simple dust mask

NOTE: Secure your work tightly as the tool might send it flying.

Tip 2 - Grinding Disc

Before starting up your angle grinder, consideration needs to be given to the choice of disc installed in the tool.

For cleaning up welds, removing heavy corrosion and shaping most kinds of metal – the basic grinding disc is the best option.

Use of a grinding disc should be avoided on aluminium surfaces with regular discs, as the material removed will block the grinding disc unless you have aluminium purpose grinding disc.

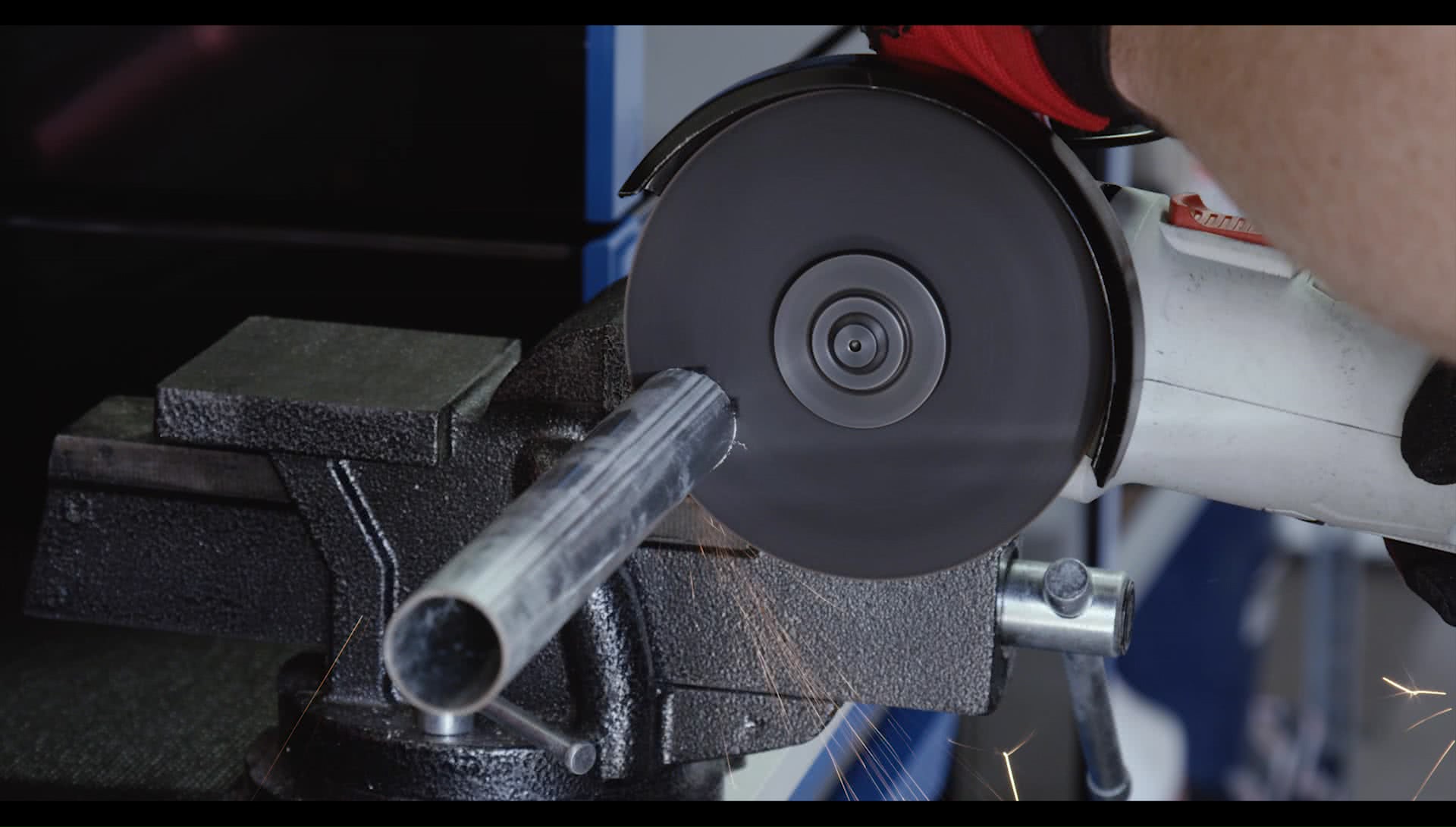

Tip 3 - Cutting Disc

To make clean cuts in sheet metal, solid bar, cut off rusted bolts and much more – you can’t go past the cut off disc.

Ensure the cutting disc you have is suitable for the material you're cutting as some will be for specific metals.

Cutting or shaping stone and ceramics such as tiles or pavers – will require a diamond disc if you want to get through more than one cut.

Tip 4 - Wire Wheel

And if you want to give an item a quick clean up; a wire wheel – will remove paint and light corrosion quickly, even in tight corners.

Tip 5 - Flappy Disc & Rapid Strip

Avaialble in 40, 80 & 120 grit sand paper, flappy discs are excellent for grinding welds, rust & paint back in quick succession.

Alternatively to flappy discs are rapid strip discs, these are great to take off paint without harming the metal underneath but do wear out quicker than a flappy disc.

Tip 6 - Setup

Many angle grinders will come with an auxiliary handle which can be installed near the head for extra grip – always make use of this if the job allows for it.

At this point, the guard can be positioned to best suit the task at hand. Some guards will require a spanner to adjust the position - while others may have a quick release mechanism.

Whatever the case, try and position the guard so that the exposed disc is pointing away from you as much as possible.

Tip 7 - Precautions

With necessary eye, hearing and safety clothing on – you are ready to start the grinder. Start the motor and allow a few seconds for the disc to reach maximum speed before you begin working.

The most important thing to be wary of when operating the tool is kick back. This occurs mostly around the edges and corners of the work piece. The best practise to minimize kick back is to ensure that the disc is spinning away from edges and corners, rather than spinning into them.

Kick back can also occur when the grinder is put under excessive load, so always go easy and let the speed of the grinder do the work.

*Important information* - Click here to read more about our How-To terms and conditions.