How To Use Feeler Gauges

Overview

When building or servicing engines and other machinery gaps and tolerances must be accurately measured.

These measurements need to be spot on, and can be obtained using measuring devices known as "Feeler Gauges".

Feeler Gauges come in a range of different combinations, from metric to imperial and even offset gauges, great for getting into hard to reach areas.

Steps

Measure the Gap

First, ensure that the gap to be measured is free of dirt or greasy build up.

Make sure that the feeler gauges are clean and well oiled also.

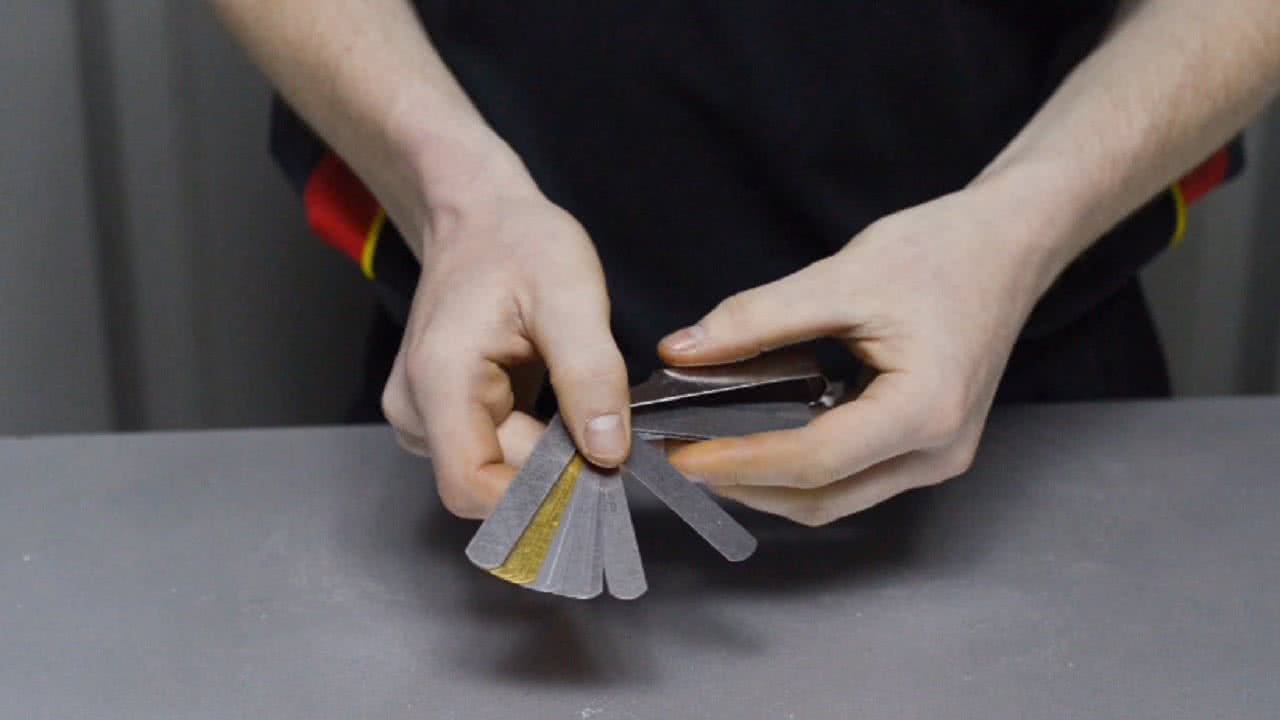

Find the Correct Blade

Next, go through your feeler gauge set to find the closest possible blade that will fit in the gap.

Fit the Blade Snuggly

Then, place the feeler gauge in the gap and check for movement.

If the blade moves too freely within the gap, stack multiple blades until a snug fit is obtained.

Feeling for resistance is key when using feeler gauges. The proper resistance can be likened to pulling a sheet of paper from under a magazine, or peeling Sellotape off a roll.

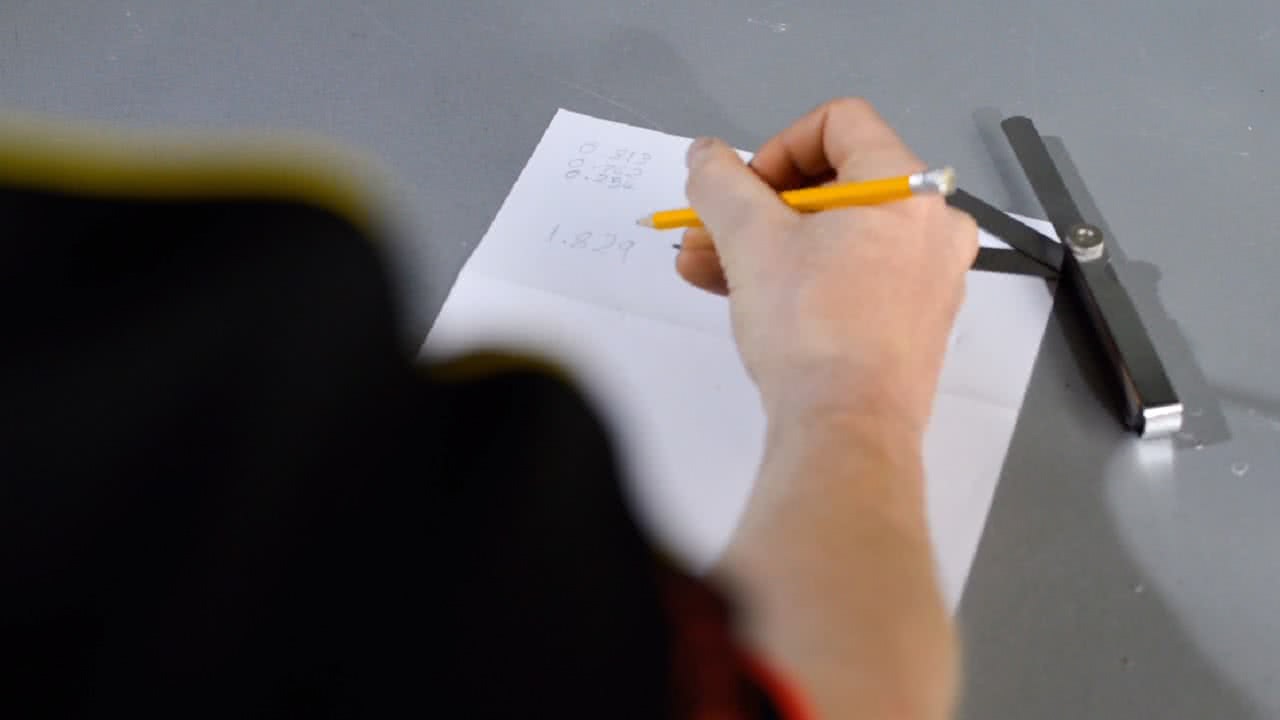

Complete

Now – add up the total thickness of all blades used and check this against a workshop manual to determine if your part is within specification.

And that's it! You have successfully measured using a feeler gauge.

*Important information* - Click here to read more about our DIY Advice Terms and Conditions.