How To Hone an Engine Cylinder

Overview

The ToolPRO range of Engine Cylinder Hones are a must have tool for de-glazing bores, and achieving a top notch results from your rebuilt engine.

Here’s how to get a perfect hone every time.

Steps

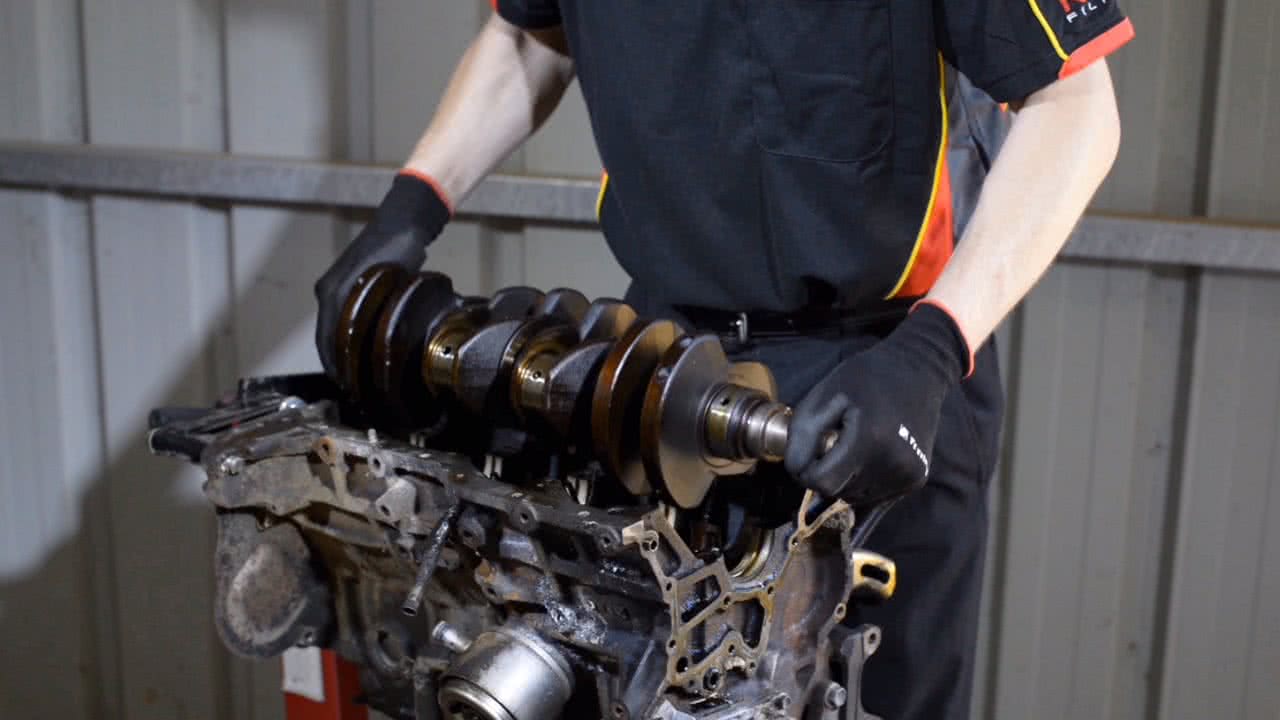

Prepare Engine Block

The engine block needs to be completely stripped before performing this task, making it easier to clean afterwards.

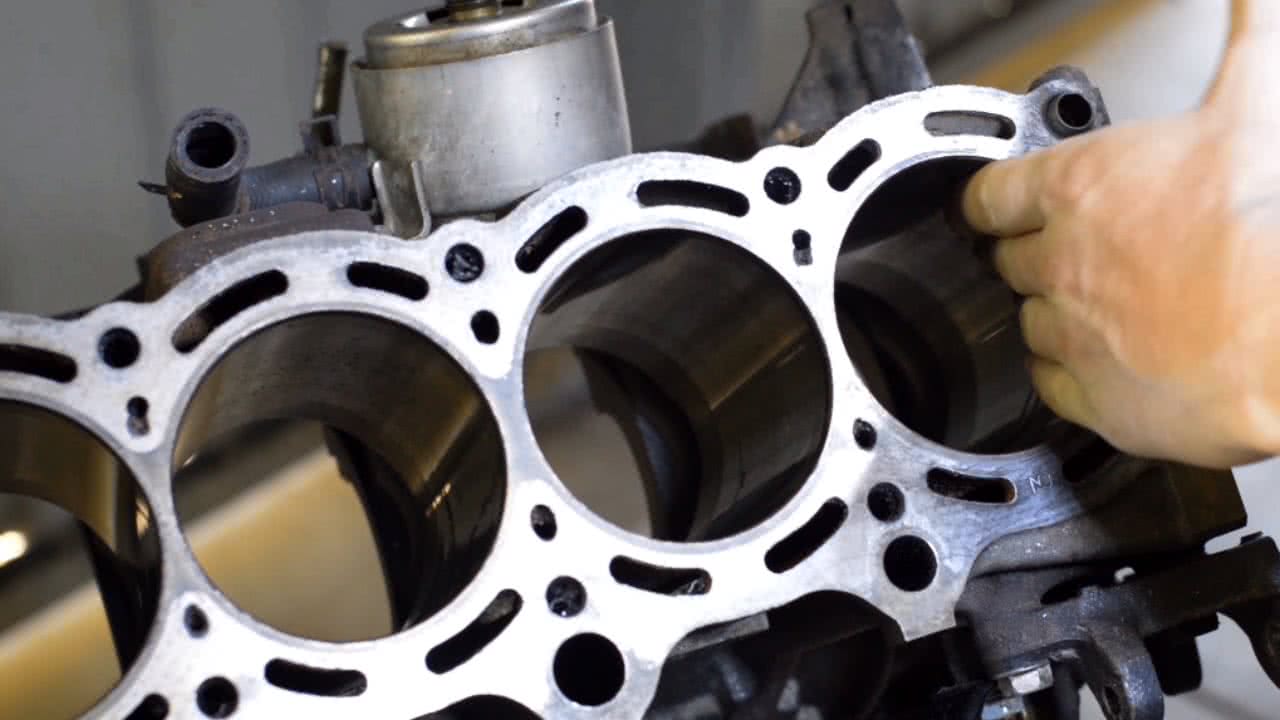

With the cylinders free of as much loose material and old engine oil as possible, wipe some honing oil, or 10W 30 engine oil around the cylinder walls.

Squeeze the honing stones together with one hand, and remove the steel retainer from between the arms.

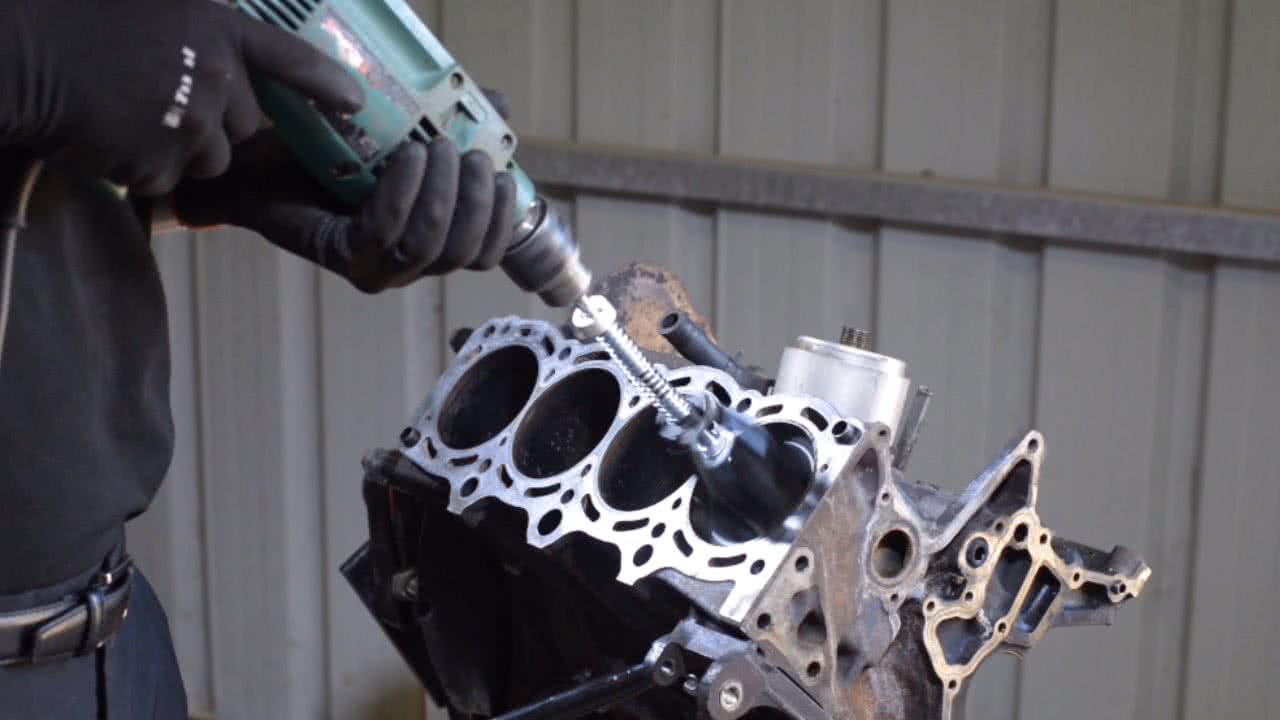

Hone Bores

With the honing tool installed on a power drill, insert the hone into the cylinder and maintain a medium drill speed, while quickly moving the drill up and down inside the cylinder.

Remove the hone and check the bore for a good even pattern. You are aiming to get a cross hatching pattern of 45 degrees.

This can be achieved with the right combination of drill speed and rate of up and down motion.

If there are still glazed sections remaining the cylinder will need further honing.

Rinse Between Passes

Rinse the hone in a bucket of warm soapy water, apply fresh oil to the cylinder walls and repeat the process.

Adjust Hone as Necessary

For a more aggressive hone, the pressure of the cylinder hone can be increased by tightening the adjuster nut downwards.

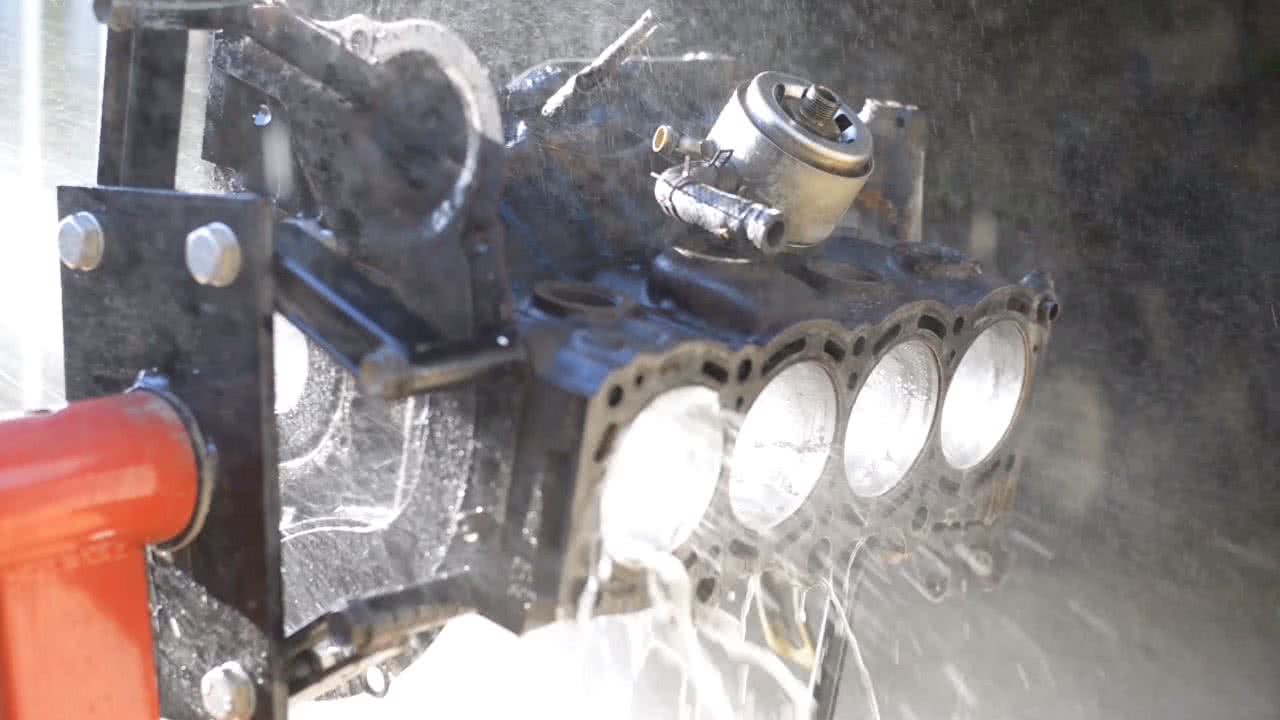

Clean Block Thoroughly

Once all of your cylinders are evenly honed, it is important to thoroughly clean the block with warm, soapy water, or a degreaser solution.

Pay extra attention to scrubbing the bores with a rag or nylon brush.

The bore can be considered clean if a white rag remains stain free when wiped around the cylinder walls.

Oil the Bores

Finally, spread some clean engine oil around the bore to ensure that no rust develops before the engine is assembled.

*Important information* - Click here to read more about our DIY Advice Terms and Conditions.